ELECTRODIALYSIS PROCESSES (ED, EDR, EDBM, EDM)

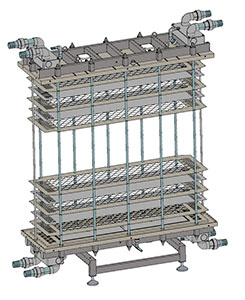

The heart of the ED process is the module (electrodialyser). The basic features are:

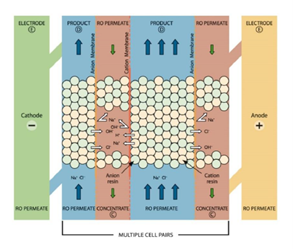

• Series of alternating ion-exchange membranes separated by spacers.

• One cation and one anion exchange membrane plus two spacers = cell pair.

• Spacers are alternately connected to internal manifolds for proper liquid distribution.

• Platinum-coated titanium electrodes.

The primary process inside the stack is transport of salt from diluate to concentrate. From the hydraulic point of view, the classic ED module consists of three independent circuits:

• the first circuit washes electrodes with electrode solution and brings the electricity to the terminal working membranes,

• the second (diluate) and third (concentrate) circuits run through chambers composed of the spacers.

Components of the ED module:

1. Manifolds with built-in collectors

2. Electrodes

3. Ion-exchange membranes

4. Spacers

5. Tie-rods, washers, and nuts

6. Assembly pins

Our R&D electrodialysis tests are performed on laboratory modules (type EDR-Z) and pilot modules (type EDR-Y and EDR-X) (see the development of custom-made devices and technologies). The industrial modules (type EDR-II, EDR-III) are in the portfolio of MEGA.

Electrodialysis module with intensive flow (EDR-IF/EDBM-IF)

The new generation ED module for high salinity water treatment in industrial applications as RO brine concentration, pre-concentration before evaporation, ZLD applications, and treatment of different types of industrial wastewater. The main advantages are:

• Up to 40% higher performance to the existing state-of-the-art EDR stacks

• Reduction of downtime for EDR technology

• Up to 30% layout reduction for EDR systems

• No internal or external leakages

• Cost reduction

• Robust design

• No burning, possible operation at higher voltage

• Possible operation at higher temperatures (up to 55 °C)

• Reduction of maintenance

• New application potential

• Improved OHS conditions

We also designed the pilot modules suitable for electrodialysis with bipolar membranes:

• EDBM-IF /2×100-0.8 – two-circuit module with arrangement cation-exchange membrane (CM) – bipolar membrane (BM) and 100 membrane pairs.

• EDBM-IF/3×100-0.8 – three-circuit module with arrangement cation-exchange membrane (CM) – bipolar membrane (BM) – anion-exchange membrane (AM) and 100 membrane triplets.

We validated these modules in the technology of processing sludge water. For more information, see Cooperation and Services and mega.cz/water/.

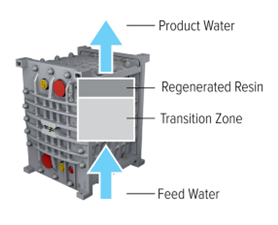

ELECTRODEIONIZATION

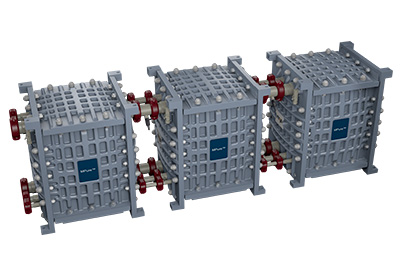

Electrodeionization (EDI) is a polishing technology for producing high-purity water. Our novel MPureTM EDI modules can produce high resistivity water with low silica levels, making it attractive for various applications, including boiler feed water production. MEGA produces three types of MPure modules:

• MPureTM 6 with 6 cell pairs and maximum flow 2,5 m3/hour

• MPureTM 12 with 12 cell pairs and maximum flow 5 m3/hour

• MPureTM 36 with 36 cell pairs and maximum flow 15 m3/hour

The essential features of MPure modules are:

• Suitable for industrial application – capable of reaching > 16 MΩ.cm product water resistivity

• Low-cost EDI system building.

• Easy maintenance.

• Modularity and redundancy.

• Small footprint.

• Robust and durable design.

• Suitable for high flowrate systems.

• Option of direct discharge of electrode stream.

For more information about industrial units, see Utrapure Water.

DIFFUSION DIALYSIS

The diffusion dialysis process enables the recovery of free acid from various waste streams (i.e. acid bath from surface treatment). For our R&D purposes, we use spiral membrane modules from our cooperating company Spiraltec GmbH. This module regenerates sulphuric acid, phosphoric acid, and hydrochloric acid.

For recovery of HNO3 (up to 20%) and HF (up to 5%) mixture, MemBrain developed modules which include hollow fibre membranes:

• DD-1: Laboratory module intended for laboratory testing of DD process.

• DD-2: Pilot module intended for verification of membrane separation quality in hollow fibre forms for DD and pilot tests of operating stability of used membranes.

• DD-3: Pilot module for acid regeneration from waste pickling baths, so far in the industrial validation process with our R&D partners.

For more information, see Cooperation and Services.

GAS MEMBRANE SEPARATION

The gas separation modules are equipped with our membranes in the form of hollow fibres. We developed laboratory and pilot modules. So far, we are in the phase of laboratory and pilot testing with our R&D partners.

Oxygenator with a hollow fibre membrane

MemBrain is a part of a successful project – inventing an oxygenator with a hollow fibre membrane. The device was invented by the Institute of Macromolecular Chemistry, the Czech Academy of Sciences (IMC), and MemBrain. This equipment produces slightly pressurised air with high oxygen content. The difference from other types of devices is the hollow fibre membrane provided in the module by MemBrain. The membrane permeates oxygen eight times faster than nitrogen, the major element of the air, and also filters 100% of all viruses, bacteria, and impurities contained in the air. Additional oxygen makes up to 45% of air content. For more information, see Oxygenator.

WE OFFER

• Design and innovation of membrane modules – custom-made solution.

• Mathematical modelling and simulation of processes.