Biogas stations serve to produce electric power and to heat buildings. We develop technologies for separation of biogas for production of biomethane, which is an alternative of natural gas. It is used to propel cars, buses, trucks and tractors under the marking of bioCNG, pressed into the gasworks network and burnt in gas boilers. More potential we see in production of pyrolysis gas, separation of nitrogen and oxygen.

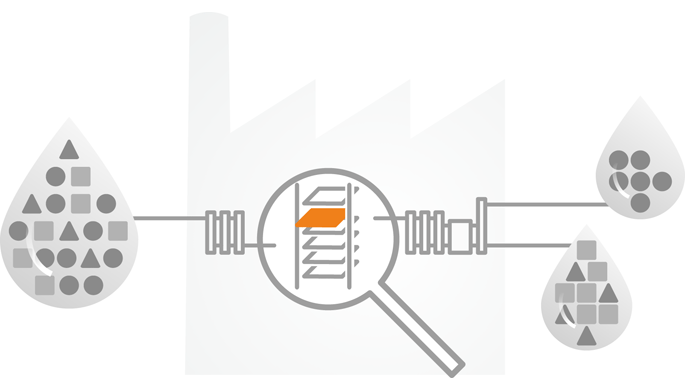

The key lies in the membrane. Through this core component, we implement a comprehensive process.

Advantages of technology:

• Verified by long-term operation - typical product over 96% methane

• The technology works without any chemicals and does not generate waste

• Technology does not consume water

• Flexible technology - technology rolls into parameters in minutes

• Zero methane losses due to system integration into a biogas plant with cogeneration

• Container design - without the need for construction clearance

• Expanding capacity of technology

• Minimum operator requirements

• low energy intensity compared to conventional technologies

• Low operating costs

• Allows for biogas with a higher oxygen content compared to conventional technologies

By cooperating with us, you obtain:

- Substantial savings on operational costs for the operation of motor vehicles

- Independence on suppliers of fuel

- Membrane technology compatible with the existing biogas station

- Economic savings in operation, resulting from intensification of the existing operations

- Environment-friendly production that generates no waste

- Know-how supporting further development of your enterprise

Document Library

-

Technology bioCNG_25

274 kB

274 kB